Have you ever been told:

“You can only achieve high positional accuracy at the expense of speed.”

Or, maybe you heard mention that:

“Long-term accuracy cannot be achieved with a system that uses drive rollers to position the timber. Build-up on the drive rollers will adversely affect the accuracy.”

Well, Vekta would like to end the debate once and for all-drive rollers, speed and accuracy can mutually exist.

Speed

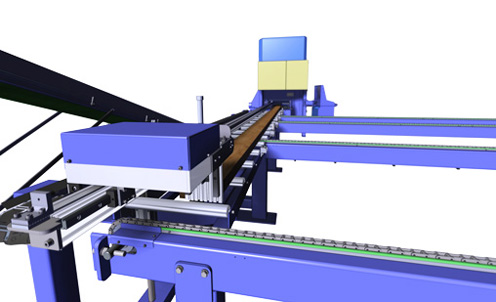

The Vekta Razer Saws use drive rollers to position the timber. Drive rollers are capable of moving timber faster and can also handle more irregular shaped members when compared to ‘grabber’ systems.

Accuracy

The Vekta Razer Saws have ‘The Follower’- a paddle that runs along a high precision timing belt and is pushed up against the trailing edge of the timber.

But how exactly do they work together?

As the timber is fed through the Razer saw using the drive rollers, the follower ‘follows’ the timber into the saw chamber. By knowing how far the follower moves, using the high precision timing belt, it is known exactly how far the timber has moved. As the timing belt on the follower is used to control the accuracy (similar to the back stop on a semi-automated pull saw), build-up on the drive rollers will not affect accuracy.

The result?

Extraordinary long-term accuracy without sacrificing speed or the ability to handle certain member shapes and sizes. If that isn’t impressive enough- The Follower allows each board to be measured before cutting begins- verifying that the correct timber has been loaded. It also allows for on-the-fly optimisation- the actual length of timber fed into the saw is measured and then optimised to cut members that best suit that specific length of timber.