Vekta is excited to announce that we have just released the newest version of our operating software, Simple Version 13. As usual, V13 adds even more printing capability to our saws but also made several steps towards providing our customers with new options to improve plant efficiency. ‘Industry 4.0’ and the ‘Internet of Things’ are the latest buzz words circulating around companies involved with Technology but really in a nutshell, they’re just about using networks in new and novel ways to make things talk together more efficiently. They’re about giving operators and managers more control and visibility of their systems from mobile or remote locations. V13, as was the case with several of our previous version releases, takes more steps towards these latest approaches and trends – ensuring our products remain relevant for many years to come. While some of our customers might not use all of the available functionality now, they will likely demand it in years to come so we’re getting started now!

Some highlights include-

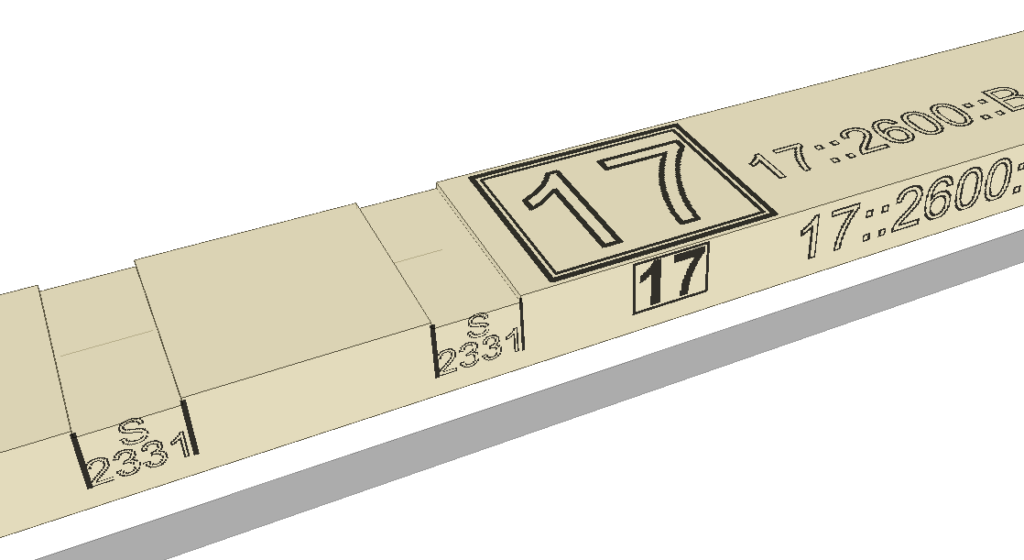

- Nail plate orientation marks (i.e. the direction of the teeth) can now be printed directly onto members. The marks conform to the industry standard for displaying nail plate orientations.

- Job files can be automatically opened, cut, saved, closed and then archived without operator intervention. This allows the operator to focus on simply making sure the saw is running – loading timber and/or stacking cut components – that’s it. Essentially, the floor manager can now simply send jobs to the saw for cutting from his office PC – no more need for someone to go back and forth to get the paperwork for the next job to cut.

- Improvements to ‘Auto Sequencing’. When a job is finished cutting, the saw can automatically jump straight over and start cutting the next job – again, without operator intervention. A screen pops up to let the operator know that they’ve moved onto a new job but the saw doesn’t stop – it just keeps going. Stoppages between jobs is another common cause of downtime.

- The saw now saves the cut files after each and every member cut – Yes I know… Something we should have added ages ago…

- Improved remote viewing and interactivity – statistics, operator screen, picklists, etc available from any device on the factory’s private network, including mobile devices.

- Continued work on remote telemetry development – a fancy way to say we are working in the background to improve the ability for the software to work in conjunction with our Perth based systems automatically.

- Improved panel marking & trenching compatibility

- Improvements to overhang markings

- Trench cuts now support partial width trenching and multi pass trenching for extra depth.